|

Home>Products>Turnkey Projects-Acid Proof Linings-Main Page

BCPL'S ACID PROOF TURNKEY SOLUTION

Introduction:

Bhise Ceramics Pvt. Ltd. now offers turnkey solutions for the installation of the Acid Proof brick lining system, wherein we supply all the material required for the installation and do the laying as well, at the hands of our skilled masons, trained exclusively for perfection.

Typical Stages of the installation:

Let us consider a platform, for storage of barrels containing spent acid, for the purpose of discussion.

Click on the individual stage for

detailed information on the

materials.

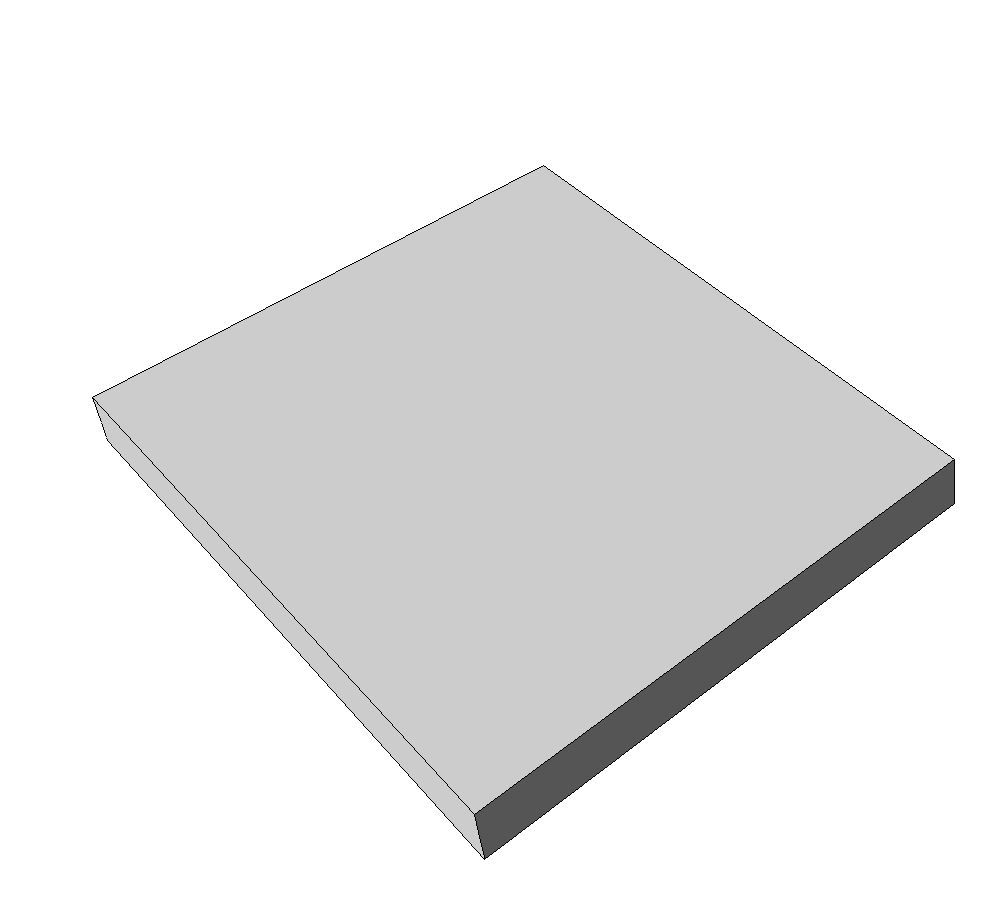

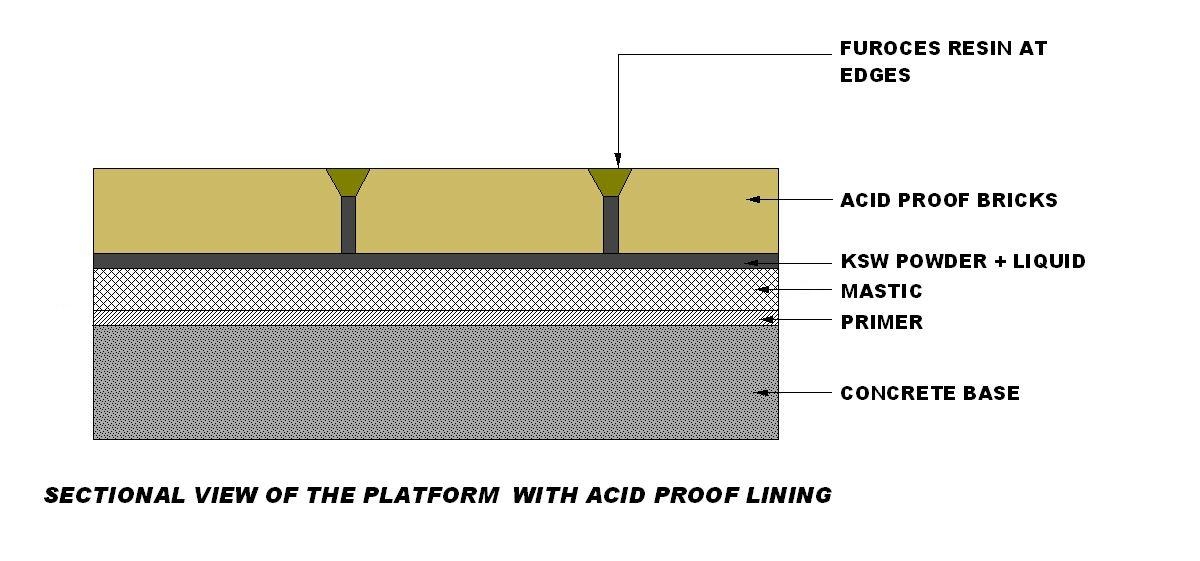

The concreting of the platform needs to be free from any surface cracks and the leveling needs to be plain, so that no repairs / surface preparation is required when the skilled masons of BCPL commence the work.

The Stage I of work is the cleaning of the platform, to remove any loose particles and to give it a rough finish, for application of the BCPL Bitumen Primer.

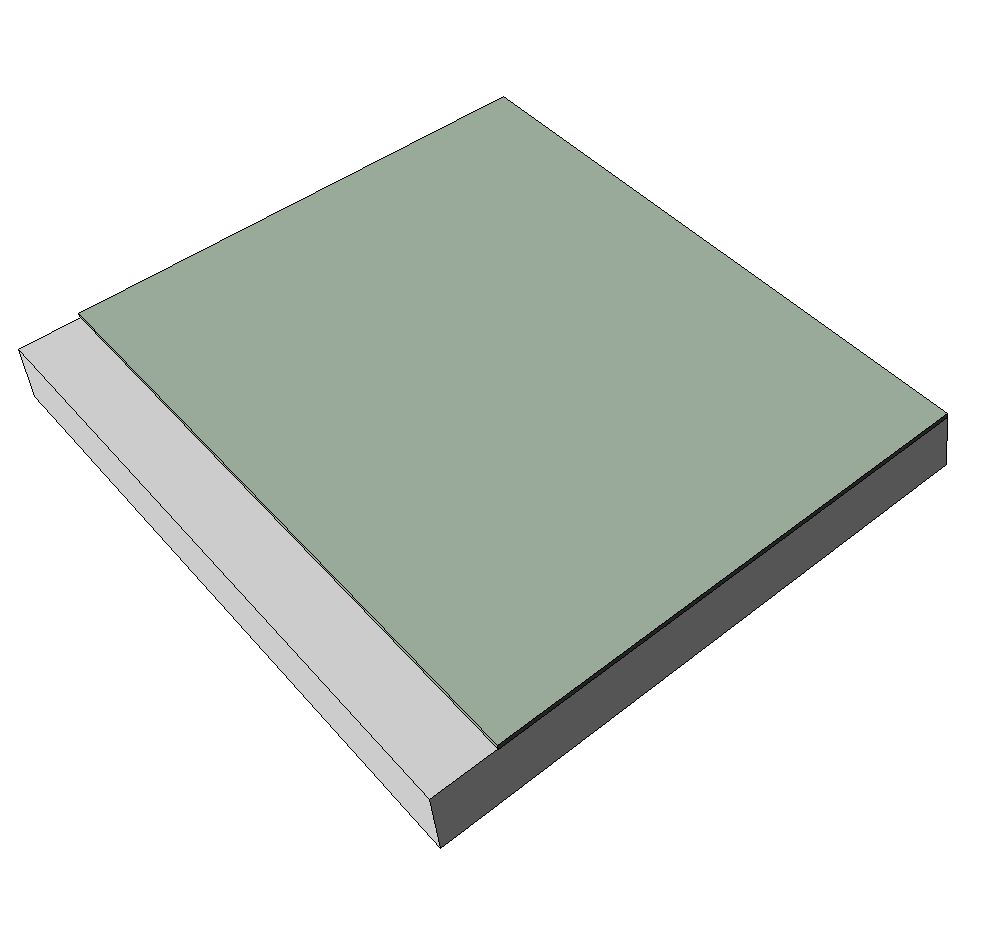

Stage II: Application of BCPL Bitumen Primer

The Second Stage involves the application of the BCPL Bitumen Primer on the cleaned concrete Surface. The BCPL Bitumen Primer creates a basic surface, ready for the application of the BCPL Acid Proof Mastic.

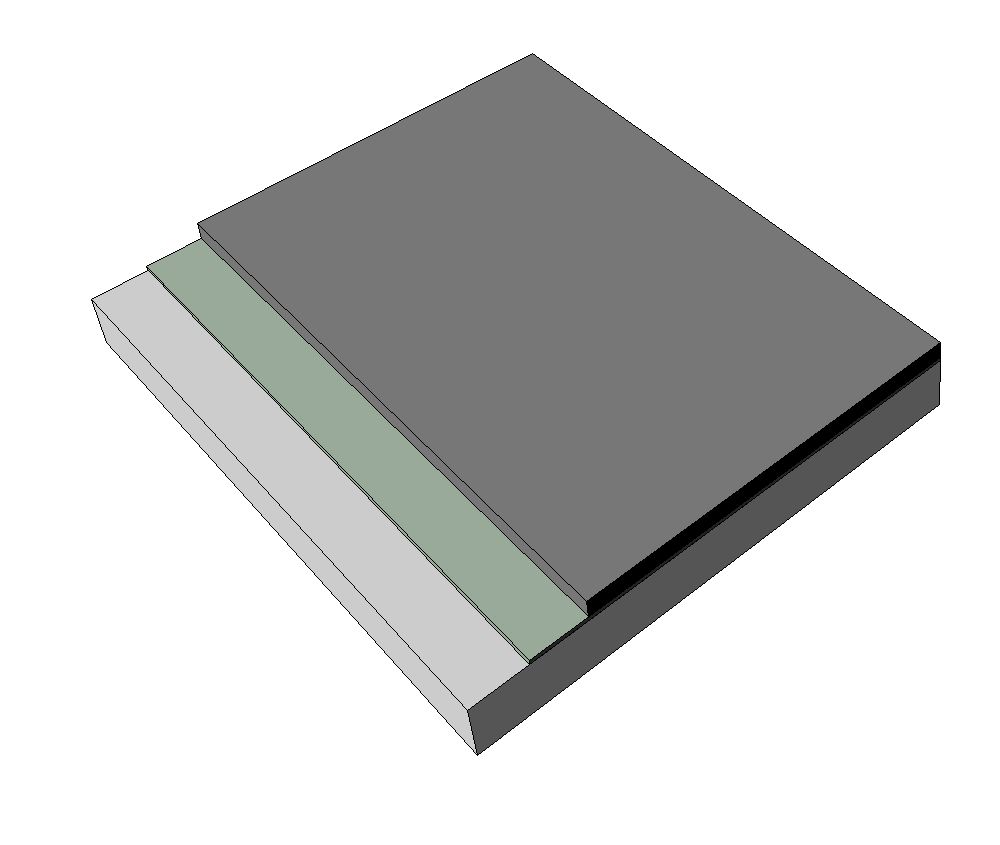

Stage III: Application of BCPL Acid Proof Mastic

Mortar

The Stage III is the application of the BCPL Acid Proof Mastic over the layer of the BCPL Bitumen Primer.

BCPL Acid Proof Mastic is the proverbial last line of defense in the Acid Proof Lining. In the event of the acid seeping through the gap between the Acid Proof Brick Lining, the BCPL Acid Proof Mastic, being a uniform layer without any joints, it does not let it go through to the concrete base.

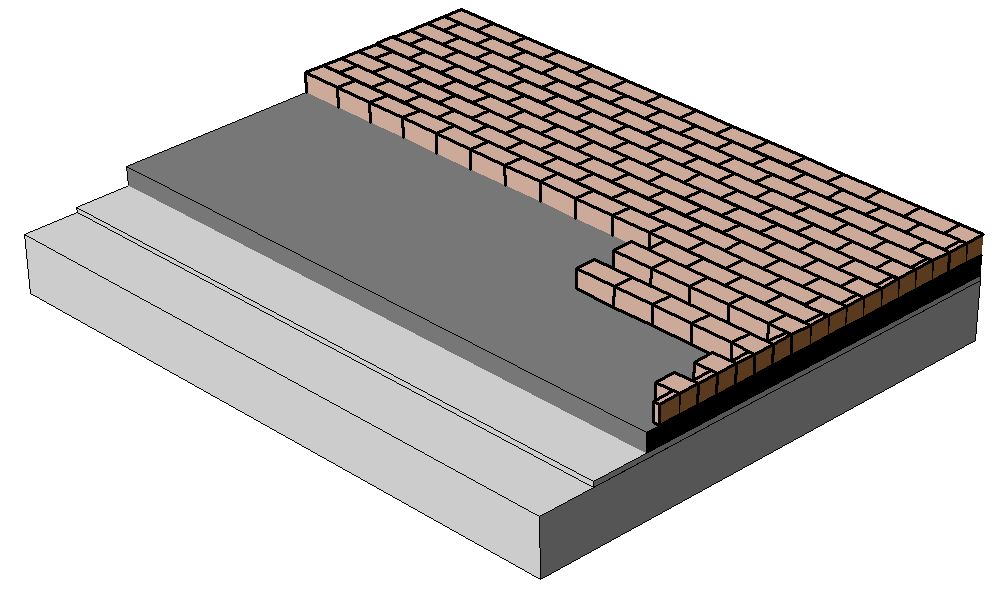

Stage IV: Laying of the Acid Proof Brick Lining and application of BCPL Furane Resin based Cement

The last stage is the laying of the Acid Proof Brick Lining, by use of

BCPL Acid Proof KSW

Cement. For better resistivity to the acid being stored, the joints between the bricks are raked and filled with BCPL Furane Resin based Cement.

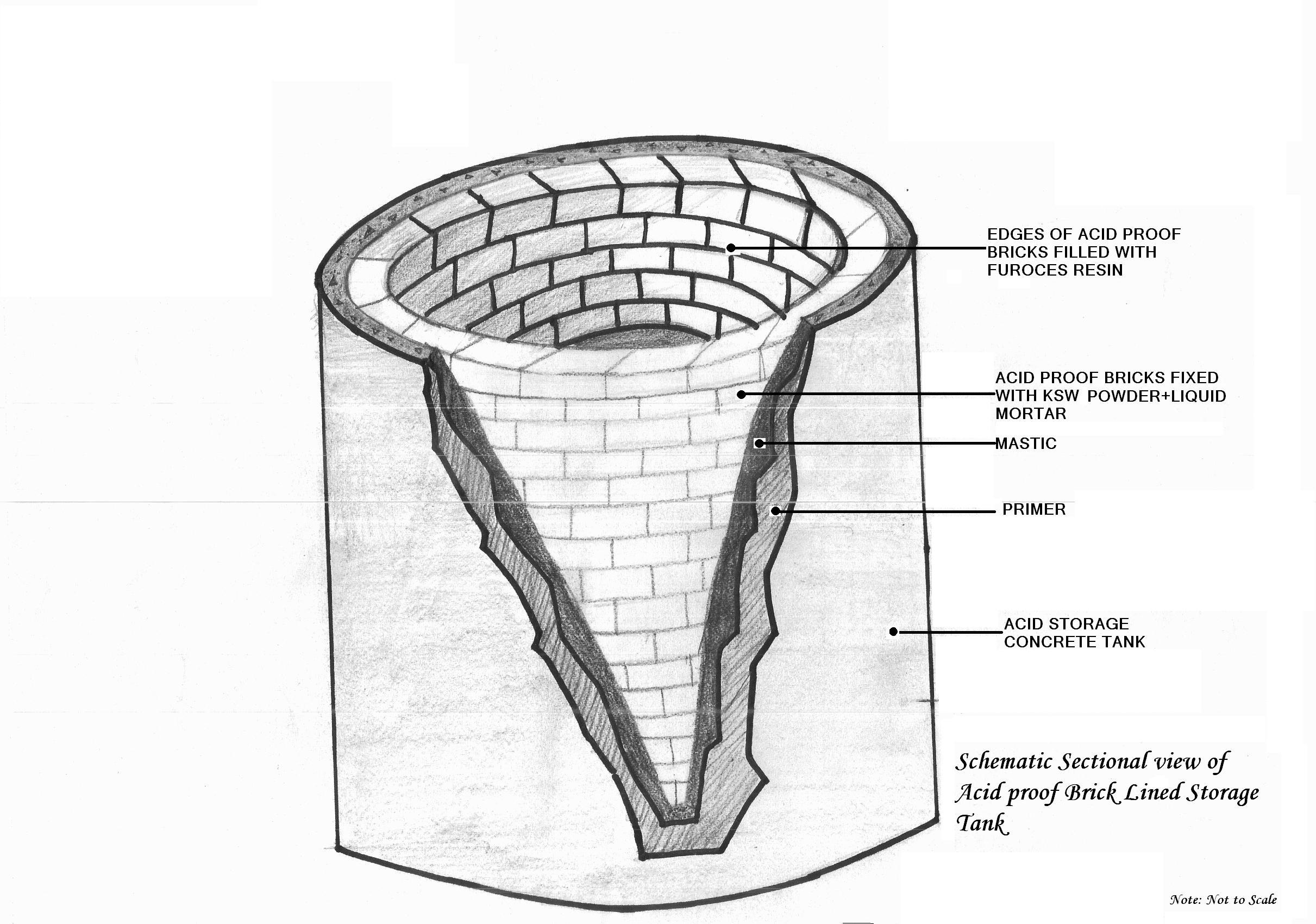

This is the overall process for the installation of the Acid Proof Lining. The process remains similar, even if we have to do the installation for storage tanks, plant areas of any other location.

The following schematic shows the typical cross-section of the Acid proof installation:

While we have considered a simple platform, it is possible to line the storage tanks, with the same systematic procedure. We have shown the typical schematic section (Not To Scale) of a storage tank overleaf as a typical illustration.

Schematic Representation of a Storage Tank with Acid Proof Brick Lining

At BCPL, we are constantly looking for new challenges to match our capabilities in installation of Acid Proof Linings. Contact us today, for a corrosion-resistance solution.

|