Ceramic Ferrules for Waste Heat Boilers and Claus

Furnaces

Introduction:

With the sulphur content of crude oil and natural gas on the increase and with the ever tightening sulphur content in fuels, the refiners and gas processors will require additional sulphur recovery capacity. At the same time, environmental regulatory agencies of many countries continue to promulgate more stringent standards for sulphur emissions from oil, gas and chemical processing facilities.

Hydrogen Sulphide (H2S) is an obnoxious and toxic gas found in crude oils and natural gas. At all temperatures,

H2S is corrosive to carbon steel and to most engineering alloys. Hence,

H2S must be removed from processed petroleum products and pipeline quality natural gas. All unprocessed refinery products typically contain sulphur. Therefore, the best place for removal of sulphur is in the refinery.

Morever, H2S that is removed must be disposed-off in the manner that does not pollute the environment as well. This is done by partial combustion in a Claus Process Sulphur Plant.

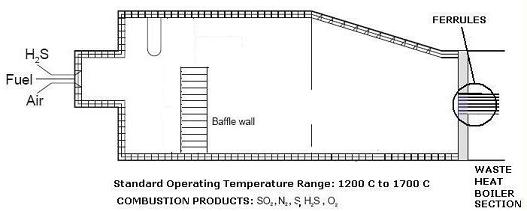

Sulfur Burner operation

The furnace is initially fired with natural gas or refinery gas, and then hydrogen sulphide gas is introduced slowly while the amount of gas is reduced to zero. Combustion of hydrogen sulphide is exothermic and self-sustaining when low levels of oxygen are maintained.

The overall reaction takes place in two stages. In the first stage, the combustion reaction converts approximately One –third of the hydrogen sulphide to sulfur dioxide. In the second

stage the sulfur dioxide and hydrogen sulphide react to form the element sulfur. The sulfur is condensed in the waste hear boiler and drained to the sulfur storage area. The residual sulfur dioxide is then converted catalytically to sulfur over bauxite catalysts in downstream convertors. Liquid sulfur is again drained directly to sulfur storage. Trace hydrogen sulphide leaving the last converter is incinerated to sulfur dioxide or is fed to a tail gas clean up unit such as a scrubber or a Shell Claus Off-gas treating process.

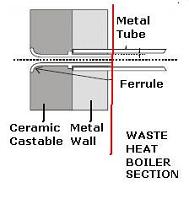

BCPL High Alumina Ferrules protect the tube inlets of the “Shell and Tube”, Heat Exchanger from hot gas corrosion and abrasive particle erosion. Operating conditions inside the Claus unit can reach temperatures 3000° F or higher because of poor combustion control and burning residual sulfur. Hydrocarbons in the feed stream also may cause sub-stoichiometric combustion conditions with temperature from 3000° F to 3300° F occurring during this period.

Design of the Alumina Ceramic Ferrules:

In specially designed High Alumina Ferrules the intermediate collar rests against the tube openings. This ensures that the refractory castable is anchored and reinforced by the extended part of the ferrule. Other Ferrules are designed with collars embedded in the refractory wall at two different distances from the hot face. The laminating effect of the collar is reduced, when these ferrules are installed alternately.

Material

Specifications:

Click here to see the

typical specifications of

Alumina 997 products